Nahttypen : Seam Types, Uses, and Expert Tips

Many sewing projects fail for a simple reason that often goes unnoticed. The fabric is good, the pattern is correct, and the machine works perfectly yet the seam breaks, twists, or looks unprofessional after a short time. In most cases, the issue is not skill or equipment. It is the wrong choice of seam type.

Nahttypen, or seam types, are the backbone of every textile product. From fashion and home textiles to industrial and technical fabrics, the seam determines durability, comfort, and visual quality. Based on my experience working with garment makers, tailoring workshops, and small production units, I have seen how a single seam decision can double the lifespan of a product or completely ruin it.

This guide explains nahttypen in a clear, practical way. It focuses on real use cases, common mistakes, and professional insights that go beyond surface-level definitions.

What Are Nahttypen? A Clear and Practical Definition

Nahttypen refers to the structural types of seams used to join two or more pieces of fabric. They define how fabric layers are positioned, stitched, and secured. This includes the seam’s construction, strength, flexibility, and suitability for specific materials or purposes.

In professional textile production, nahttypen are often standardized through DIN and ISO systems to ensure consistency and safety. These standards are especially important in workwear, medical textiles, and technical fabrics. However, the same principles apply to everyday sewing, tailoring, and DIY projects.

Understanding nahttypen allows you to choose seams that match fabric behavior, stress points, and end use instead of relying on trial and error.

Why Choosing the Right Seam Type Creates Real Value

The right seam type improves more than appearance. It directly affects durability, comfort, and performance. A properly selected seam distributes stress evenly, prevents fabric distortion, and survives repeated washing and movement.

In commercial production, correct nahttypen reduce returns and repairs. In tailoring, they signal craftsmanship and quality. For home sewers, they prevent frustration and wasted materials. A seam that fits the purpose saves time, money, and effort over the long term.

From a sustainability perspective, better seam choices also extend garment life, which reduces textile waste, an increasingly important factor in modern manufacturing.

Common Seam Types and Where They Are Used in Practice

One widely used seam type is the lapped seam, where one fabric layer overlaps another. This seam is known for strength and is commonly found in denim, workwear, and heavy fabrics that face high stress.

The plain seam is formed by joining two fabric edges together. It is simple, versatile, and suitable for lightweight to medium fabrics. This seam appears frequently in everyday clothing and interior textiles.

The flat-felled seam is more complex but extremely durable. It encloses raw edges and creates a clean finish on both sides. High-quality shirts, jeans, and professional garments often rely on this seam type. In my experience, clients consistently associate this seam with premium workmanship, even if they cannot name it.

Specialized nahttypen also exist for elastic fabrics, safety garments, and medical textiles, each designed to meet specific functional demands.

Common Myths and Mistakes Around Seam Types

A frequent misconception is that stronger seams are always better. In reality, overly rigid seams can fail faster when used on elastic or lightweight fabrics. Flexibility often matters more than raw strength.

Another common mistake is ignoring the relationship between seam type, thread, and fabric. Even a correct seam type can fail if the thread is too weak or incompatible with the fabric structure. Machine settings and stitch length also play a critical role.

Many problems also arise from poor seam allowances. Insufficient allowance weakens the seam, while excessive allowance can cause bulk and discomfort.

Real-World Applications Across Different Industries

In the fashion industry, seam types influence both function and design. Visible seams can become decorative elements, while hidden seams create a clean, minimalist look. Designers choose nahttypen as part of the aesthetic language of a garment.

In technical textiles, such as protective clothing or automotive fabrics, seam types are tested under strict conditions. Here, nahttypen are not optional choices but safety-critical components that must pass load and durability tests.

Medical textiles rely on specialized seam constructions that reduce contamination risks and withstand sterilization. These examples show that seam types are not just technical details but essential functional elements.

Step-by-Step Guide to Choosing the Right Seam Type

Start by evaluating the fabric. Consider thickness, elasticity, weave, and surface sensitivity. Next, identify stress areas. Will the seam experience pulling, stretching, or frequent washing?

Then define the product’s purpose. Clothing, upholstery, and technical textiles all require different seam behavior. After narrowing down the options, test the seam on a fabric sample. This step is often skipped but saves significant time later.

Through years of practice, I have learned that testing one seam sample can prevent multiple production errors. It is one of the most effective professional habits in sewing.

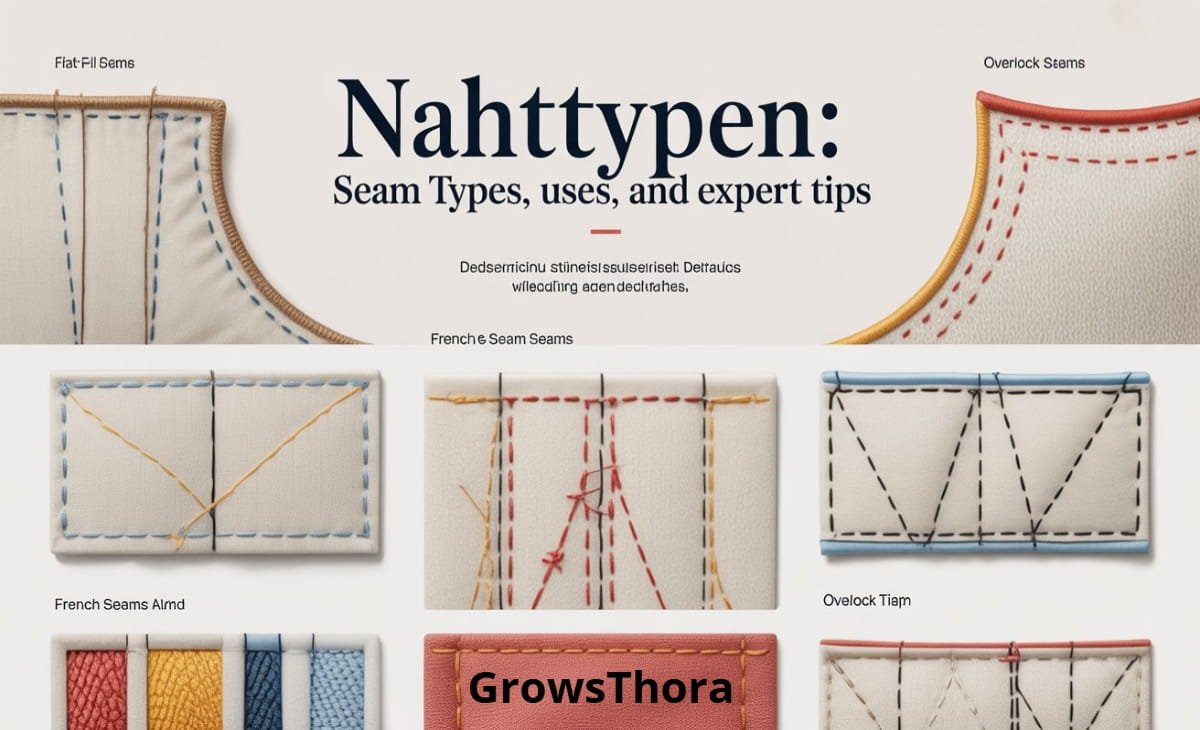

Visual Support That Improves Understanding

Diagrams showing fabric layers in different seam types help readers visualize construction differences. Close-up images of finished seams allow easy comparison of strength and finish.

For advanced users, stress-distribution illustrations are useful to understand how forces act on different seam types. Visuals like these significantly improve decision-making and reduce mistakes.

Frequently Asked Questions

What seam types are best for beginners?

Plain seams and basic lapped seams are easiest to learn and suitable for many projects.

Which seam types are the most durable?

Flat-felled seams and reinforced safety seams provide excellent durability when correctly applied.

Are there seam types specifically for elastic fabrics?

Yes, flexible seam constructions such as flat seams are ideal for stretch materials.

Why do seams break even with good machines?

The most common reason is an incorrect combination of seam type, thread, and fabric.

Are standardized seam types important?

In industrial and safety-related applications, standardized seam types are essential for quality and compliance.

Conclusion

Nahttypen are not minor technical details. They define how long a textile product lasts, how comfortable it feels, and how professional it looks. Understanding seam types allows you to work more efficiently, reduce errors, and achieve consistent results.

If you want to deepen your knowledge, explore textile standards published by organizations such as ISO or research institutions like the Hohenstein Institutes. On your own website, consider internally linking to related topics such as fabric selection or sewing machine setup for a stronger content structure.

Call to Action: Test different seam types on the same fabric and observe the results. Share your findings, explore advanced techniques, or consult a professional to elevate your work.