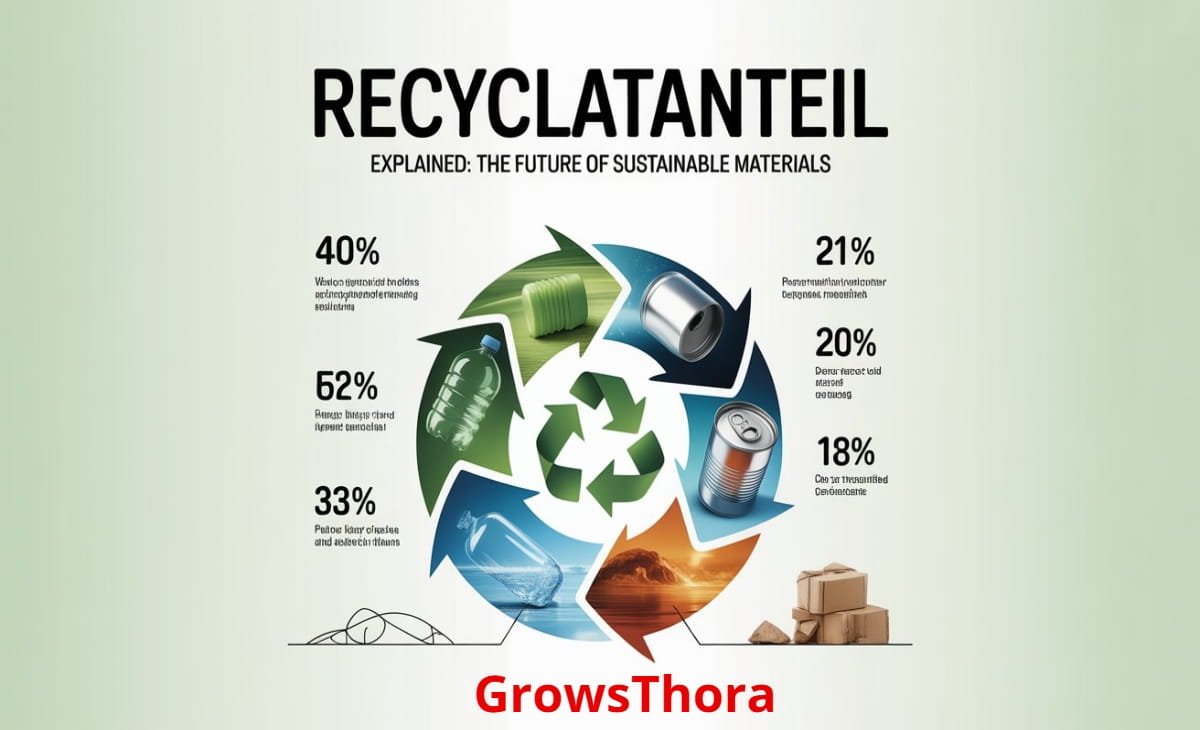

Recyclatanteil Explained: The Future of Sustainable Materials

Sustainability today is no longer a marketing buzzword. It has become a legal, economic, and ethical necessity. Whether you are a manufacturer, brand owner, packaging designer, policymaker, or environmentally conscious consumer, one term is appearing more and more in regulations, reports, and product labels: recyclatanteil.

Recyclatanteil simply means the percentage of recycled material used in a product. But behind this simple definition lies a powerful transformation in how products are designed, how supply chains operate, and how industries define responsibility. From plastic bottles and food packaging to textiles, construction materials, and electronics, recyclatanteil is becoming one of the most important sustainability indicators in the modern economy.

As someone who has worked with sustainability audits and circular economy frameworks, I have seen firsthand how companies struggle not with the idea of recycling, but with measuring, proving, and scaling recycled content. This article is written to go beyond surface-level explanations and provide real understanding, practical guidance, and strategic insight into what recyclatanteil truly means in real-world business and environmental impact.

What Does Recyclatanteil Mean?

Recyclatanteil refers to the proportion of recycled material in a product compared to the total material used. For example, if a plastic bottle contains 30% recycled PET and 70% virgin plastic, its recyclatanteil is 30%.

This concept is central to the circular economy model. Instead of the traditional linear system of “extract, produce, use, discard,” recyclatanteil supports a circular flow where materials stay in use for as long as possible through recovery, processing, and reintegration into new products.

In technical and regulatory language, recyclatanteil can include:

Post-consumer recyclate, which comes from used consumer products like bottles, packaging, or textiles.

Post-industrial recycling, which comes from manufacturing waste such as production offcuts and rejected materials.

Many sustainability standards differentiate between these two, because post-consumer recycled material has higher environmental value due to actual waste reduction.

Why Recyclatanteil Matters More Than Ever

The growing importance of recyclatanteil is not driven by trends alone. It is being pushed by regulations, climate policies, consumer behavior, and economic realities. Governments are introducing recycled content quotas, especially for plastic packaging and construction materials. The European Union’s circular economy action plan and packaging directives are clear examples of how recyclatanteil is becoming a compliance requirement, not a voluntary choice.

From a business perspective, increasing recyclatanteil reduces dependence on virgin raw materials, which are becoming more expensive and politically unstable due to resource scarcity and geopolitical risks. From an environmental point of view, higher recycled content reduces carbon emissions, energy consumption, landfill pressure, and pollution. In consumer markets, recyclatanteil builds trust. People are no longer satisfied with vague sustainability claims. They want measurable, verifiable impact. A product that clearly states its recycled content is easier to trust than one that simply says “eco-friendly.”

Benefits of High Recyclatanteil for Businesses and Society

A higher recyclatanteil creates value at multiple levels. Environmentally, it lowers CO₂ emissions and resource extraction. Economically, it stabilizes supply chains and reduces material dependency. Socially, it strengthens environmental responsibility and brand credibility.

In my professional experience, companies that invest early in recycled material systems are more resilient to regulatory changes. They adapt faster to new laws and avoid costly last-minute compliance transformations.

High recyclatanteil also improves ESG scores, which are increasingly important for investors, banks, and insurance providers. Sustainability is no longer just about ethics; it directly affects access to capital.

Challenges, Myths, and Risks Around Recyclatanteil

One common myth is that recycled materials are always lower quality. While this was often true in the past, modern recycling technologies have significantly improved material purity, strength, and performance.

A real challenge, however, is traceability. Many companies cannot accurately verify how much recycled material is actually in their supply chain. Without certification systems, recyclatanteil claims can become unreliable.

Another risk is greenwashing. Some brands highlight small recycled percentages while hiding the overall environmental impact of production. This damages trust and can lead to legal consequences.

Supply consistency is also a challenge. Recycled material streams are not always stable in volume or quality, especially in developing recycling infrastructures.

Real-World Applications of Recyclatanteil

In packaging, recyclatanteil is now a standard KPI. Beverage companies use recycled PET (rPET) in bottles. Food brands integrate recycled cardboard in boxes. Cosmetic brands shift to recycled plastic packaging. In construction, recycled aggregates, metals, and plastics are increasingly used in infrastructure projects.

In fashion, recycled polyester from PET bottles is now common in sportswear and outdoor clothing. One real-world example I worked on involved a mid-sized packaging company transitioning from 0% to 40% recycled content within two years. The biggest challenge was not sourcing material, but redesigning processes and supplier contracts. The long-term result was cost stability and regulatory readiness.

How Companies Can Increase Their Recyclatanteil

The process starts with material mapping. Companies must understand what materials they use, where they come from, and how they can be replaced with recycled alternatives.

The second step is supplier integration. Recyclatanteil is not an internal issue alone. It requires collaboration across the entire supply chain.

Certification systems such as ISCC, FSC, and Global Recycled Standard (GRS) help verify recycled content and prevent greenwashing.

Process adaptation is essential. Recycled materials often require different production parameters, testing, and quality control systems.

Finally, transparency matters. Clear communication of recyclatanteil builds trust with customers and regulators.

Visual Content Suggestions

A circular economy flow diagram showing material life cycles from waste to new products would help readers understand recyclatanteil visually.

A comparison chart showing CO₂ emissions of virgin material vs recycled material would clearly demonstrate environmental benefits.

A supply chain diagram explaining traceability and certification systems would improve comprehension for business readers.

Frequently Asked Questions

What is recyclatanteil?

Recyclatanteil is the percentage of recycled material used in a product compared to total material content.

Is a higher recyclatanteil always better?

Generally yes, but quality, safety, and certification must also be considered to ensure real sustainability impact.

How is recyclatanteil verified?

Through certification systems, audits, supplier documentation, and material traceability systems.

Does recyclatanteil reduce carbon emissions?

Yes, recycled materials usually require less energy and produce lower CO₂ emissions than virgin materials.

Is recyclatanteil legally required?

In many regions and industries, recycled content quotas are becoming mandatory, especially in packaging.

Conclusion

Recyclatanteil is no longer just a technical sustainability term. It is a strategic indicator of how seriously a company, product, or industry takes environmental responsibility. It affects regulation, branding, supply chains, investor trust, and long-term business survival. The companies that lead the future will not be those who market sustainability, but those who structurally build it into their materials, processes, and decisions.

If you want to future-proof your business, improve compliance, and build real sustainability credibility, start by understanding your recyclatanteil and then start improving it. Explore deeper sustainability strategies, get expert guidance, or integrate recycled content into your operations today. The circular economy is not coming, it is already here.